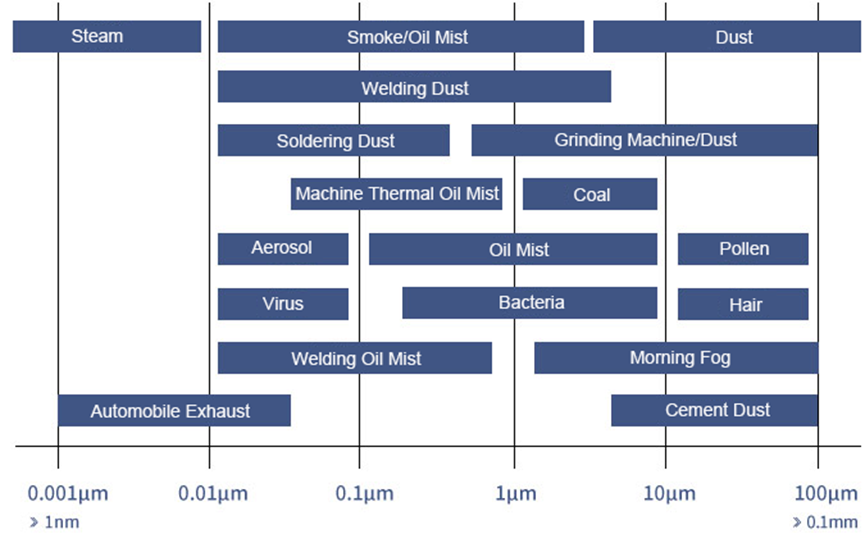

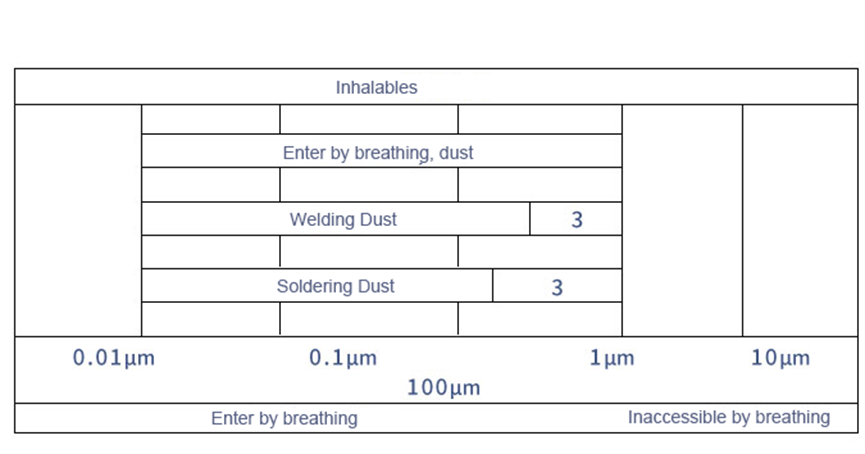

Welding dust particle size usual under 10um, which is PM10 respirable dust, some particle sizes are as small as 2.5um and below, which is called PM2.5 fine dust. Breathe in PM10, PM2.5 dust for a long time, which will cause various adverse effects on human health, such as pneumoconiosis is the most common, more serious carcinogenic and neonatal malformation, which is not easy to be discovered in time, but once it occurs, it will be an irreparable harm.

Welding dust particle size usual under 10um, which is PM10 respirable dust, some particle sizes are as small as 2.5um and below, which is called PM2.5 fine dust. Breathe in PM10, PM2.5 dust for a long time, which will cause various adverse effects on human health, such as pneumoconiosis is the most common, more serious carcinogenic and neonatal malformation, which is not easy to be discovered in time, but once it occurs, it will be an irreparable harm.

Due to the fact that most of the welding workpieces have a certain amount of oil on the surface in the laser welding condition. According to different laser welding conditions, Kaisen adopts the treatment form of cartridge fume extractor or wet dust collector. Through design simple welding room, the dust generated from welding station can be effectively absorbed, and the fume that is not absorbed will also be contained in its independent welding room, collected and processed finally, without polluting the environment of other spaces in the workshop.

Cartridge Fume Extractor: For the workpiece is contained oil in laser welding when need use cartridge fume extractor, there should be equipped powder spraying device in front of the cartridge fume extractor, which can prolong the service life of the filter cartridge as much as possible while ensuring the dust removal effect.

Wet Dust Collector: Wet dust collector is mainly used for the condition such as the oil on the surface of the workpiece, a large number of sparks in the grinding process and other. Wet dust collector eliminates ignition source and sufficient oxygen, doesn't need to be equipped with fire extinguishing device and enhanced cartridge filter, reduced safety hazards in factory production, which more responsive to the country's green and safe production.