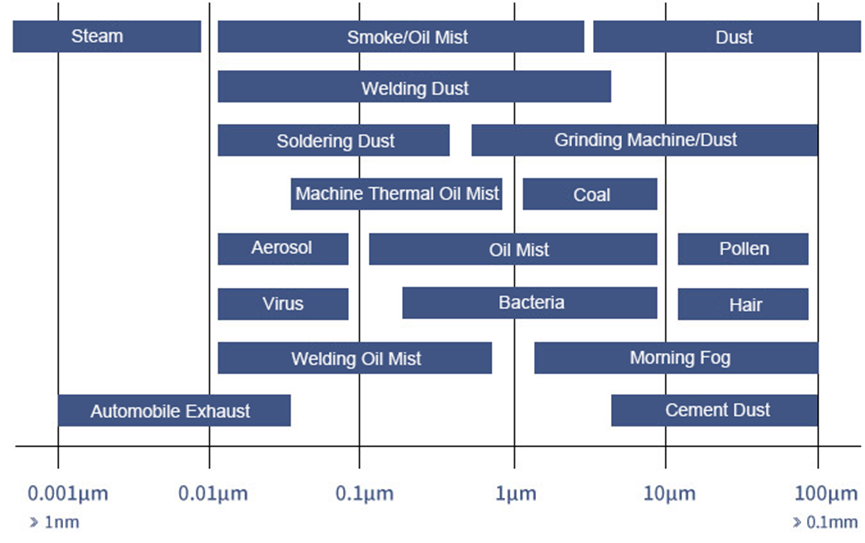

Welding dust particle size usual under 10um, which is PM10 respirable dust, some particle sizes are as small as 2.5um and below, which is called PM2.5 fine dust. Breathe in PM10, PM2.5 dust for a long time, which will cause various adverse effects on human health, such as pneumoconiosis is the most common, more serious carcinogenic and neonatal malformation, which is not easy to be discovered in time, but once it occurs, it will be an irreparable harm.

For Integral welding workshop, Kaisen provide different types of dust removal systems according to the actual situation, which include industrial dust collector tower, integrated treatment all-one machine, self-circulation purifying tower, blowing type purification system and other treatment form. Form a circulating air flow for the workshop part or the whole, and equipped with advanced monitoring alarm function, workshop environmental real-time data detection and other industry specific needs.

Industrial Dust Collector Tower: Vertical design, 12 air supply and return sides, small footprint and multilayer design, innovative design of upper return air and lower air supply that ensures the operators can continuously breathe fresh air in work area, multi-gear free adjustment and controllable air volume. The device is like a large household air purifier, ensures the air quality in the factory.

Integrated treatment All-one Machine: Adopts high performance centrifugal fan, large air flow, unique design makes the can be sucked on the above and below the work surface, capture efficiency is greatly improved; don’t need pipeline, flexible host installation position; the tuyere can be adjusted according to working specific condition and dust density, and in summer and winter, the cost of heating and cooling can be greatly reduced.

Self-circulation Purifying Tower: Innovative appearance and vertical multi-faceted adjustable design; innovative upper return air and lower air supply that ensures the operators can breathe fresh air in work area continuously, multi-gear free adjustment and controllable air volume, reduce energy consumption. Not only can response the complex and exchange working environment, but also don't need intricate construction pipeline, with multiple functions and flecible mobility.

Blowing Purifying System: The air with dust enters the purifying system for a high-efficiency filtration, clean air is exhausted through the exhaust duct, and air outlet is designed on the exhaust duct. First, set a large air flow on the suction port, capture dust continuously, and then set a higher speed blowing force, blow the air to the suction side continuously, and form a push-pull air movement. This way of continuously forming convection, not only effectively reduces the concentration of the dust in the suspension layer, but also brings the gas outside the suspension layer into inertial flow. This dynamic method of changing the airflow organization in the workshop, equipped with a high effective dust purifying system, can effectively improve the air environment in the workshop.